Henry Sikazwe

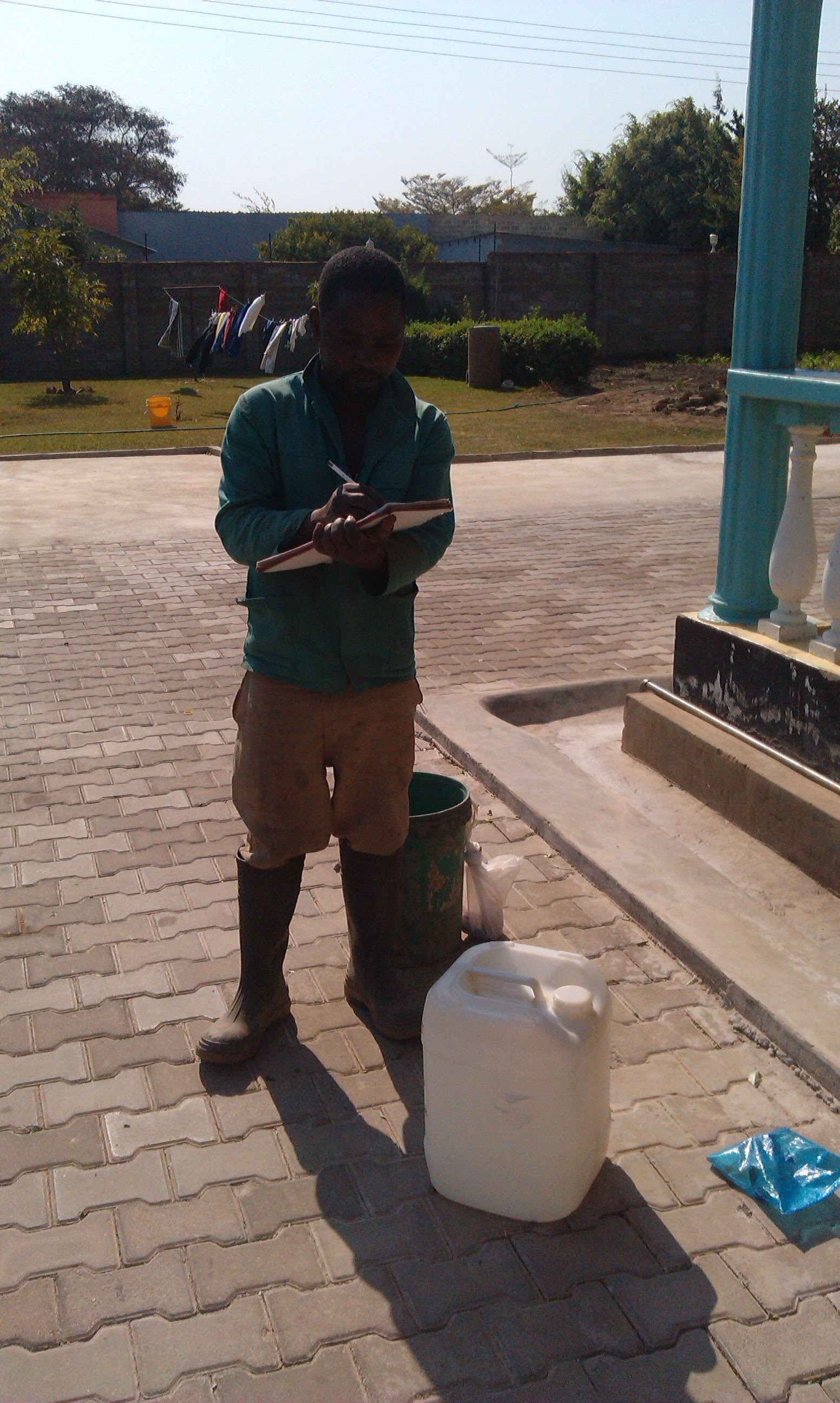

Speaking to a floricultural entreprenuer Who agreed to help us show other farmers how to be succesful in that lucrative field.

.jpg?1538787704105)

Henry Sikazwe

Speaking to a floricultural entreprenuer Who agreed to help us show other farmers how to be succesful in that lucrative field.

'Just Two Buckets' is an Initiative started by Likhwa Ndlovu, Dennis Mashindi, Josh Upadhay Henry Sikazwe and Mphatso Simbao in Lusaka Zambia to educate agriculturists to make the most of natural biochemical processes so that they can increase their income without relying expensive inputs or becoming dependent on aid. At the moment, Henry is continuing the work with the agribusiness owners in Lusaka while Josh handles the American side of the project. The project focuses on using an informal outreach based curriculum to teach farmers about drought management, pesticides and anaerobic digesters as a cheaper way of improving their yields and increasing their incomes. It is a social entrepreneurial project that seeks to help uneducated farmers to have more unconventional agricultural money making systems.

The project focused on using an informal outreach based curriculum to teach farmers about drought management, biopesticides and anearobic digestors as a cheaper way of improving their yeilds and increasing their incomes. It is a social entreprenuerial project that seeks to help uneducated farmers to have more unconventional agricultural money making systems.

We are extremely thankful to Kate Reiling, Joddy Emmings, Jenny Moeller and Macalester College's Live it Fund grant that allowed us to get started. We are also extremely grateful to Mr and Mrs Simbao (Mphatso's mom and dad) for their advice, guidance and patience through out the project. Most of all we thank God for answering our prayers and helping us to be able to make lasting impact in our community that we hope to keep working on going forward.

In one bucket, we cultivated microbes from cow dung to create a mini biodigester that we used to produce fertilizer faster than conventional composting and cheaper than chemical fertilizers. We then used the first slurry to help other farmers make their own digesters using their own buckets.

We started with mini digesters to help them understand the science well on a small scale then encouraged them to expand creatively on their own and be able to troubleshoot if we aren't around. Many farmers have moved the slurry to larger tanks and vats and infact now have large biodigesters which we will start helping them to use to collect gas from and not just fertilizer slurry.

In another bucket, we made a mini biodigester but fed it with acidic wastes so that the slurry had a low pH that we used as a pesticide for aphids. This was only applied on the leaves.

This was the main part of the project. So far we have 90 farmers with mini-digesters that we will convert to fully functioning biodigesters to make gas with for the households.

An alternative usage for buckets was using them to transport fingerlings. The fingerlings were not grown in the buckets but in a large communal pond (it took the two of us 4 days) to keep them in. 500 fish have so far been stocked but the pond has a capacity of 1000.

We started this alternative because it was simple but effective based on the aquaponics systems we learnt about from an aquaculturist consultant in Lusaka. We decided to use the green pond water to water our plants since it would contain many minerals from the fish waste (like in aquaponics) while giving us a good place to store water to deal with water shortages.

We use the buckets for measuring feed (they have numerical scales on the inside wall), transporting water to a large reservior for the plants and holding fingerlings when they are being moved or acclimatized to new water.

We are looking to build and encourage farmers to have more communal ponds that can act as a shared source of food, revenue, water, storage site for rain water and recreational area in the community.

We also found that we could use buckets to make simple worm farms by keeping the worms in a cool soil inside the buckets under a shade. The worms were fed kitchen and yard waste and we got worm castings in just a week for zero the cost of storebought fertilizers and a fraction the time of conventional composting.

Worm castings (a.k.a Black gold) are an amazingly good fertilizer a very lucrative business in Western countries. Unfortunately, very few African farmers knew about this. We wanted to include this to the project so that they could learn houw to make their own rich fertilizer quickly using worms and yard waste. This could be used for growing crops or to set up a business to help farmers become more financially sufficient.

We left our first worms in a large "mother" farm we built and allowed them to multiply (from 25 to over 5000) so we will be able to share them with farmers and while teaching them to care for the worms.

.jpg?1538798817101)

From the pilot, we found that many farmers agreed that the best way to help increase their revenue and quality of life was indeed by increasing the inputs they had access to. They were also very knowledgable about different farming techniques that could do this but only a small handful implemented these. The biggest factor that hindered their implementation was cost. Out of the three different farming methods we tried out in the pilot, the one that provided extremely efficient farming inputs at the lowest cost with low maintenance was worm farming. Thus going forward, we are trying to build large worm farms - coupled with data science - for at least 1,000,000 farmers in Lusaka province by 2020 to help drastically increase their revenue. This is a novel approach in Zambia because worm farming so far is only done by a single major company (ecowiz) but they do it for profit and do not provide a training profit. We would be the first organization to provide training for worm farming as well as allowing a large amount of individual farmers to produce their own fertilizer in this non-conventional way.

1. Increased pest and disease suppression for crops fed with worm castings.

2. Increased soil Water Retention.

3. Highly nutritious fertilizer produced for zero costs much faster than conventional composting (days compared to months).

4. Rapid degradation and cleaning of farm land organic wastes and fertilizer production

5. Extremely Easy Instructions that don't require too much knowledge to start and can allow us to help a huge amount of people.

To do this, we first made a small prototype that was 1.5 x 1.5 x 0.5 cubic metres using recycled bricks to demonstrate to farmers what the worm farms would look like. The worms farms will be extremely simple and easy to use, build and manage even if children were left in charge of them if their parents had other work to do. They will be continuous batch systems where organic waste is added to the bin daily or weekly and worm castings (aka 'black gold fertilizer') is harvested after a week. We will combine this with data science to build an online platform that allows farmers to monitor when their casting are ready as well as how many worms are in their farms. We want to use this to deliver at most efficiency to how worm farms will be working by making calculations using a machine learning model and having a simple sms message powered by service that allows us to communicate with farmers that have no access to the internet (at least 60%).

Prototype under construction.

Our 'mother farm' where we will grow and prototype our digital worm farm using data systems to make management efficient.

Protoype results

Coincidentally, a pumpkin seed fell into the worm farm and grew to be the largest pumpkin plant we've ever seen (in life and on that plot of land). Sadly, it died due to the worm farm soil having too much fertilizer which is bad for pumpkins. Great unexpected results though (◕‿◕✿)

For Visiting our site.

We would love to hear from you! Please don't hesitate to email if you would like to help out with the project, get more information, get more pictures or just to talk!

msimbao@macalester.edu

Twalamonana! (See you Soon!) (ノ◕ヮ◕)ノ*:・゚✧